Types of Gears

What’s the Difference Between Spur, Helical, Bevel, and Worm Gears? Carlos Gonzalez | Jul 30, 2015. Gears are a crucial part of many motors and machines. Gears help increase torque output by providing gear reduction and they adjust the direction of rotation like the shaft to the rear wheels of automotive vehicles. Here are some basic types of gears and how they are different from each other ...

Answers.com ® WikiAnswers ® Categories Technology Engineering What is a parallel gear? What is a parallel gear? ... Gears are a toothed machine part, ...

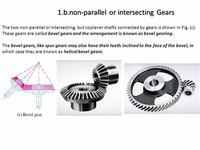

The gears that have non-intersecting shafts are hypoid gears, crossed helical gears and worm gears. These gears provide an effective answer for power transmission ...

Hypoid bevel gears in a car differential This feature is used in many car differentials. The ring gear of the differential and the input pinion gear are both hypoid.

Manufacturers, suppliers and wholesale exporters of non intersecting gears, non parallel gear, non intersecting shafts gear, non parallel intersecting gears, neither parallel nor intersecting, non intersecting gears manufacturer, non parallel gears supplier, non intersecting gear exporter from India.

Divide the teeth numbers of the drive and driven gears. The important thing to remember when dealing with gear trains with more than two gears is that only the driver and …

Rack and pinion gears from a household scale Rack and pinion gears are used to convert rotation into linear motion. A perfect example of this is the steering system on many cars.

Spur gears are mounted in series on parallel shafts to achieve large gear reductions. The most common gears are spur gears and are used in series for large gear reductions. The teeth on spur gears are straight and are mounted in parallel on different shafts.

Worm gears are used when large gear reductions are needed. It is common for worm gears to have reductions of 20:1, and even up to 300:1 or greater. Many worm gears have an interesting property that no other gear set has: the worm can easily turn the gear, but the gear cannot turn the worm.