Types of Wood Joints

Splines add both strength and visual appeal to normally weak miter joints, especially when you make the spline from a contrasting wood species. Cutting the spline slots on your tablesaw requires a tall jig, but you can cut them easily and quickly with your biscuit joiner and the attached fence jig, see drawing below.

Bridle Joint Bridle joints are very similar to the mortise and tenon joint but the difference is in the size of the mortise and tenon. Because these joints still have a mortise and tenon they are still very strong and fairly attractive.

A dado (US and Canada), housing (UK) or trench (Europe) is a slot or trench cut into the surface of a piece of machinable material, usually wood. When viewed in cross-section, a dado has three sides. A dado is cut across, or perpendicular to, the grain and is thus differentiated from a groove which is cut with, or parallel to, the grain.

Dovetail joints are commonly used to build boxes, drawers, and cabinets. The shape of the "tails and pins" in the joint make it nearly impossible to break. Glue is used to strengthen the joint but no screws or fasteners are necessary.

A finger joint, also known as a comb or box joint, is a woodworking joint made by cutting a set of complementary rectangular cuts in two pieces of wood, which are then glued, with filler.To visualize a finger joint simply interlock the fingers of your hands at a ninety degree angle; hence the name "finger joint." It is stronger than a butt joint or lap joint, and often contributes to the ...

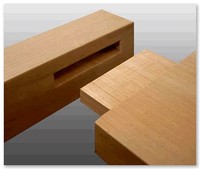

The mortise and tenon joint functions by inserting one end of a piece of wood into a hole in another piece of wood. It's that simple. The smaller end of the wood is the "tenon," and the wood with the hole in it is referred to as the "mortise." Glue is used to secure the pieces together and variations on the joint also use pins and and wedges to lock the joint in place.

What makes it precise is the design of the pocket hole jig that guides the drill bit into the wood at a specific angle to produce an engineered hole to house the screw head. After the pocket hole is drilled, a specially designed fastener is used to assemble the joints.

The most common form of rabbet joint is what I call the single rabbet joint. Only one of the mating parts is rabbeted. The cut is proportioned so its width matches the thickness of the mating board, yielding a flush fit. The depth of the rabbet for this joint should be one-half to two-thirds its width.

Tongue and groove is a method of fitting similar objects together, edge to edge, used mainly with wood, in flooring, parquetry, panelling, and similar constructions. Tongue and groove joints allow two flat pieces to be joined strongly together to make a single flat surface.