Types of arc Welding

Consumable electrodes and sticks are used in both Shielded Metal Arc Welding, or “stick” welding, and Gas Metal Arc Welding, either MIG or MAG. These consumable electrodes don’t just help form the arc: they usually contain a filler metal that melts into the weld as the stick is consumed. Using a consumable electrode is the most popular method for welding steel. Arc welding with consumable electrodes creates a lot of spatter, smoke and noise.

Shielded Metal Arc Welding, otherwise known as manual metal arc welding or flux shielded arc welding, is a process that uses a flux-coated electrode to form the weld. As electricity passes through the electrode, the flux forms a gas, which shields the electric arc in the space between the electrode and the metal being welded, preventing contamination from atmospheric gasses in the weld.

Atomic hydrogen welding (AHW) is an arc welding process that uses an arc between two tungsten electrodes in a shielding atmosphere of hydrogen. The process was invented by Irving Langmuir in the course of his studies of atomic hydrogen.

Carbon arc welding is a process in which the joining of metals is produced by heating with an arc between a carbon electrode and the work. No shielding is used. Pressure and/or filler metal may or may not be used. Carbon Arc Welding Equipment. Electrodes. Carbon arc welding electrodes range in size from 1/8 to 7/8 in. (3.2 to 22.2 mm) in diameter. Baked carbon electrodes last longer than graphite electrodes.

Electroslag welding (ESW) applications are similar to electrogas welding. The main difference is that the arc is started between the electrode tip and the bottom of the part to be welded. Flux is added, which then melts by the heat of the arc.

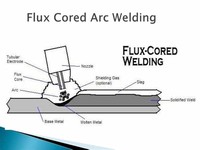

Information on the basics of flux cored arc welding to advanced welding techniques. FCAW electrode designations, machine settings, joint preparation (including ceramic backing tape), self shielding vs dual shielding and all position welding.

Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power supply.

Gas metal arc welding (GMAW) is a fusion welding process, which uses an electrical arc as the source of energy that causes the metal fusion to occur. The electrode used in gas metal arc welding is also the filler metal consumable. An external shielding gas is used to protect the molten weld puddle.

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld.

MIG and TIG welding both use an electric arc to make the weld. MIG welding is a very simple and easy process to learn compared to learning how to TIG weld. The technical names for these are metal inert gas (MIG), and tungsten inert gas (TIG).

In Plasma-arc Welding (PAW) is an arc welding process, a concentrated plasma arc is produced and directed towards the weld area. The arc is stable and reaches temperatures as high as 33,000°C. A plasma is an ionized very hot gas composed of nearly same numbers of electrons and ions.

Shielded Metal Arc Welding, otherwise known as manual metal arc welding or flux shielded arc welding, is a process that uses a flux-coated electrode to form the weld. As electricity passes through the electrode, the flux forms a gas, which shields the electric arc in the space between the electrode and the metal being welded, preventing contamination from atmospheric gasses in the weld.

Welding rod selection for stick welding is pretty straight forward. For the purpose of steel machinery repair, a 6011 will do. A 6011 is a good general maintenance rod. For the purpose of steel machinery repair, a 6011 will do. A 6011 is a good general maintenance rod.

Submerged arc welding (SAW) is a common arc welding process. The first patent on the submerged-arc welding (SAW) process was taken out in 1935 and covered an electric arc beneath a bed of granulated flux.

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld.

MIG and TIG welding both use an electric arc to make the weld. MIG welding is a very simple and easy process to learn compared to learning how to TIG weld. The technical names for these are metal inert gas (MIG), and tungsten inert gas (TIG).